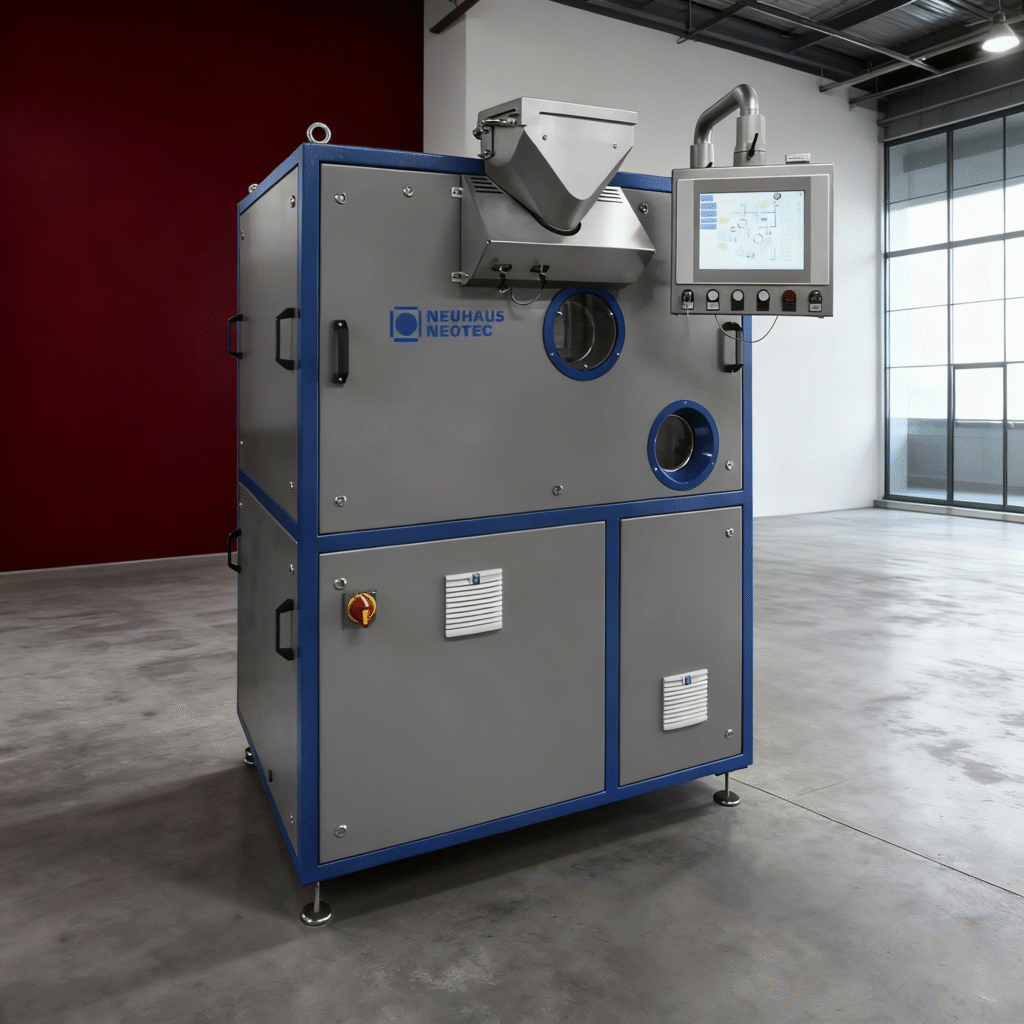

Neuhaus Neotec – Gourmet 1500

Benefits-

- Higher Capacity. Centralized Control.

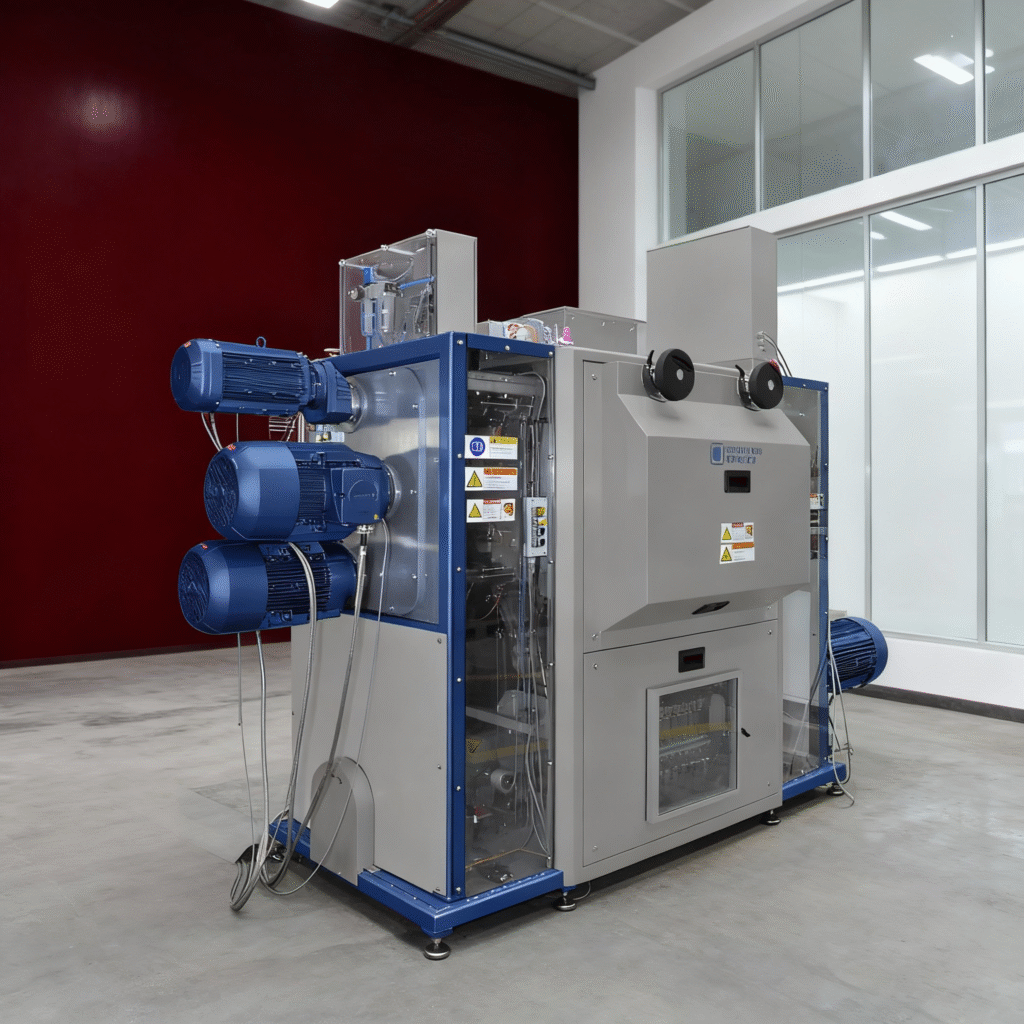

- Roast 50–165 kg per batch

- Throughput up to 1,500 kg/hour

- Centralized control room for full process management

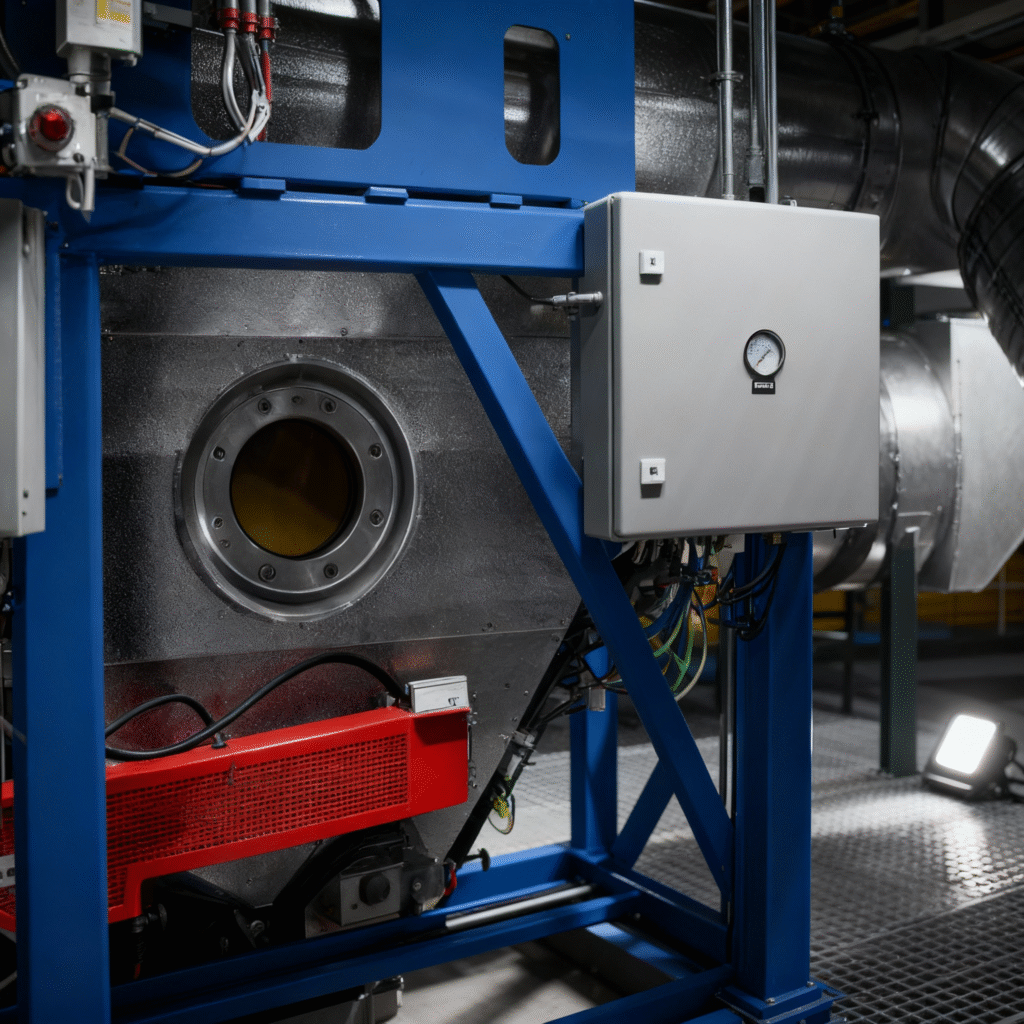

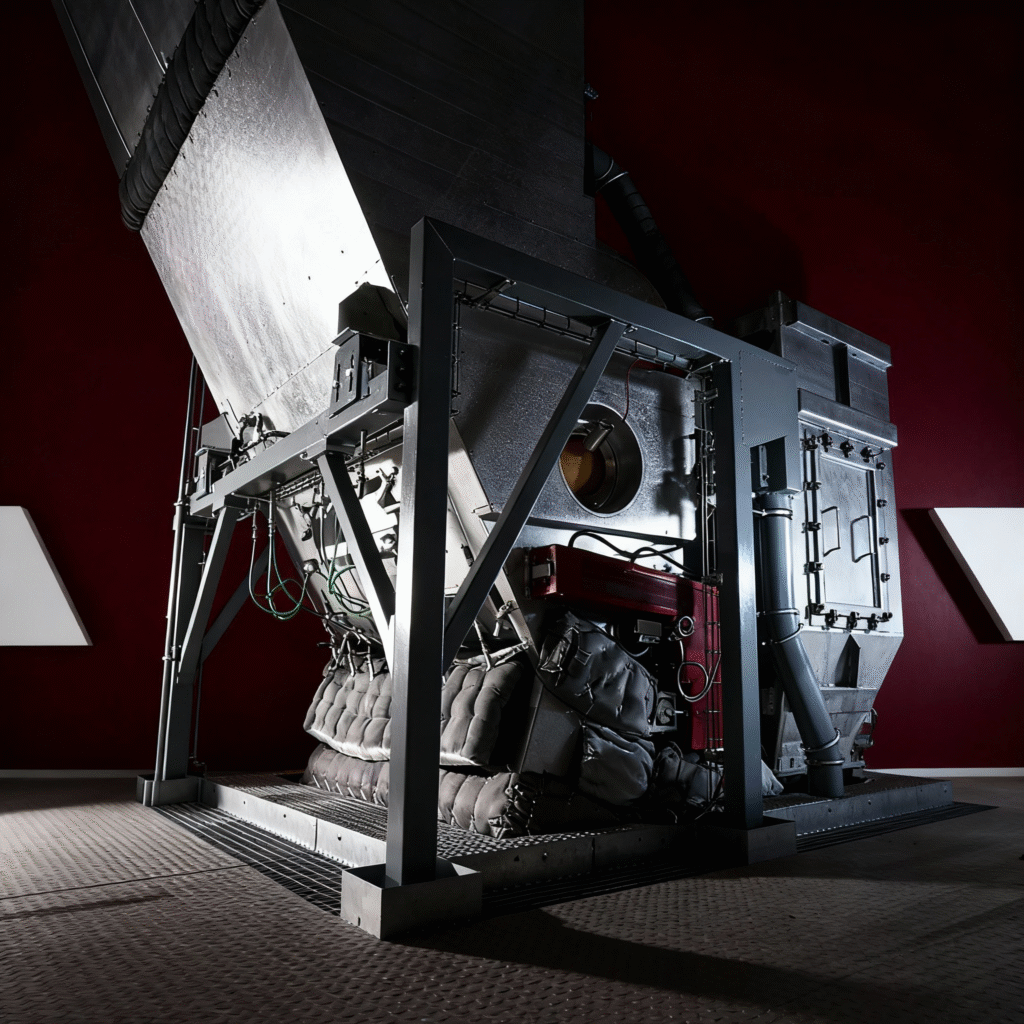

- RFB hot-air roasting for gentle, uniform quality

- Hot air recirculation reduces energy costs

- Profile roasting with automated recipe management

- German-engineered reliability for 24/7 operation

- Optional green-coffee preheating for higher efficiency

The GOURMET 1500 (formerly RG 60) is built for medium-to-large roasteries requiring consistent, industrial-scale roasting. Using RFB hot-air technology, it delivers uniform roast quality across batch sizes from 50–165 kg, with a throughput of up to 1,500 kg/h. The integrated control room allows operators to oversee, adjust, and manage the roasting process centrally, simplifying multi-batch operations. Hot air recirculation lowers energy demand, while optional green-coffee preheating can cut costs and increase throughput by 15–20%.

- Manufactured by Neuhaus Neotec

- Made in Germany.

- Batch Size: 50–165 kg per roast

- Capacity Range: 30%–110% of batch size; Nominal Capacity: up to 1,500 kg/hour

- Control System: Centralized control room with recipe automation

- Integration: Interfaces with CROPSTER and ARTISAN for analytics

- RFB hot-air chamber with recirculated air for efficiency,

- Control room with recipe and process management,

- Profile roasting with automated storage and repeatability,

- Flexible batch handling (30%–110% range)

- Optional green-coffee preheating for output boost,

- Emission treatment options: catalytic,

- RTO, UV-C photo-oxidation

Product Statement

Industrial roasting made simple—the GOURMET 1500 combines high capacity with centralized control for consistent, energy-efficient results.