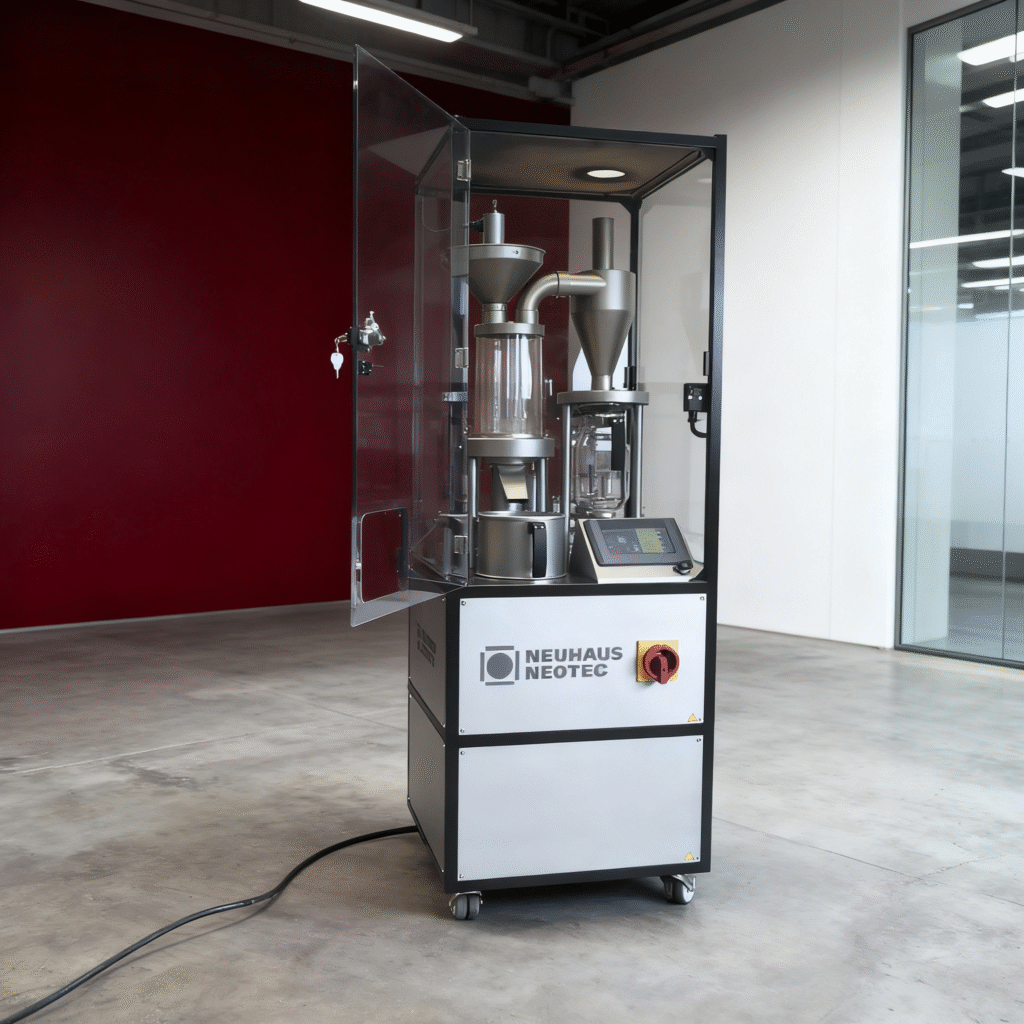

Neuhaus Neotec – Neogrind

Benefits-

- Finest Precision. Maximum Flexibility.

- Specialized for capsules, pods, and single-serve coffee

- 3-stage grinding with compactor for density control

- Individually driven rollers with flexible speed control

- Water-cooled rollers and compactor ensure stability

- Motor-driven gap adjustment for precise PSD control

- PLC automation with recipe storage

- Quick roller change and full chamber access

- Compact design with soundproof enclosure

The Neogrind was developed for sophisticated capsule and single-serve requirements, ensuring precise control of the particle size distribution (PSD). With 3-stage grinding, motor-driven gap adjustment, and individual roller drives, it offers maximum flexibility and reproducibility. A powerful compactor optimizes bulk density, while water cooling maintains stable conditions even under heavy loads. The integrated PLC allows recipe storage, profile control, and easy integration into process systems. Large chamber doors and a quick-change system simplify cleaning and maintenance.

- Manufactured by Neuhaus Neotec

- Made in Germany.

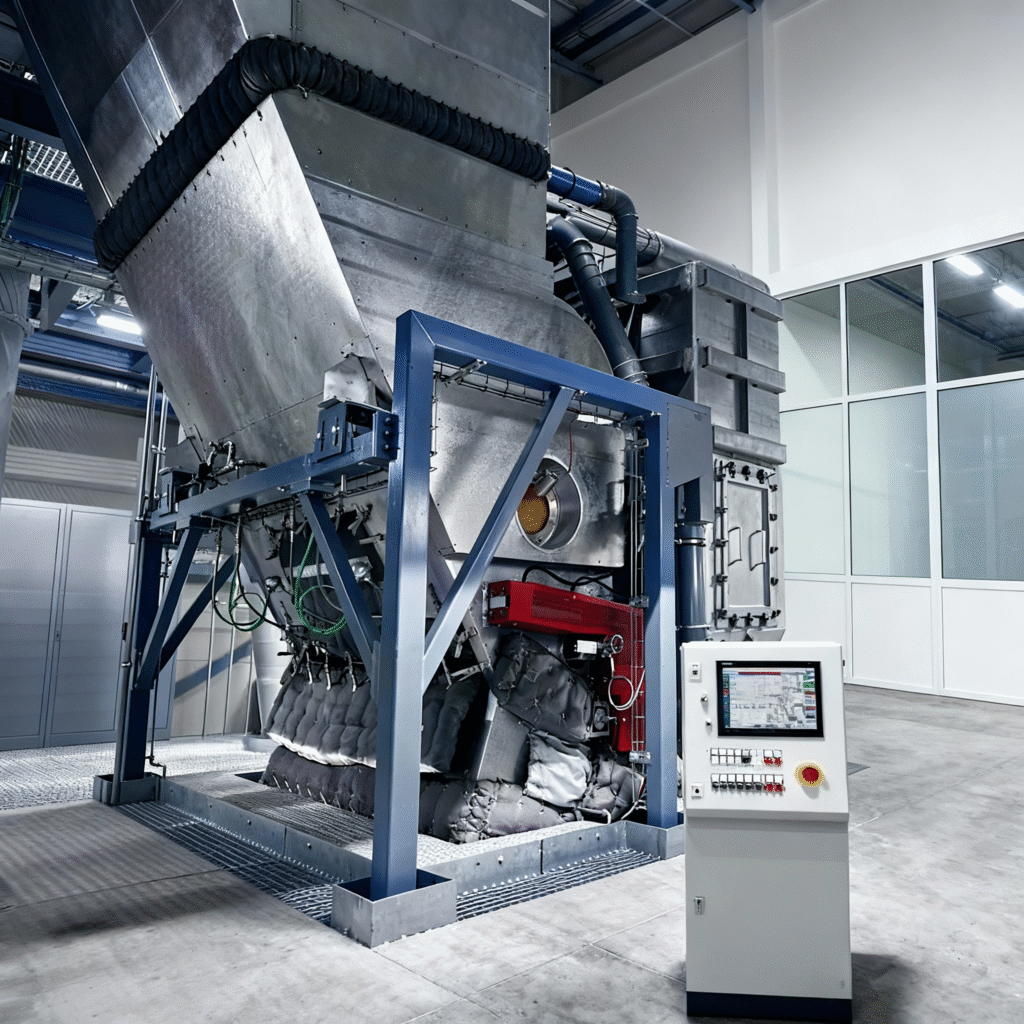

- NEOGRIND 53: 3 passages, 550 mm rollers, 3220 × 1020 × 2300 mm, 1000–1650 kg/h

- NEOGRIND 83: 3 passages, 800 mm rollers, 3470 × 1020 × 2300 mm, 1450–2400 kg/h

- 3-stage grinding with motor-driven gap adjustment,

- Powerful compactor for capsule density optimization,

- Water-cooled rollers and compactor for stable grinding temperature,

- PLC with recipe control,

- storage, and visualization,

- Individual motor drive for each roller,

- Quick roller change system and full access for cleaning,

- Sensor package monitors bearing temperatures,

- vibration, pile-up, water flow,

- Product temperature measured at inlet and outlet,

- Soundproof enclosure for quiet operation

Product Statement

Designed for the single-serve era—the Neogrind delivers precise, reproducible grinding and density control for capsules and pods.