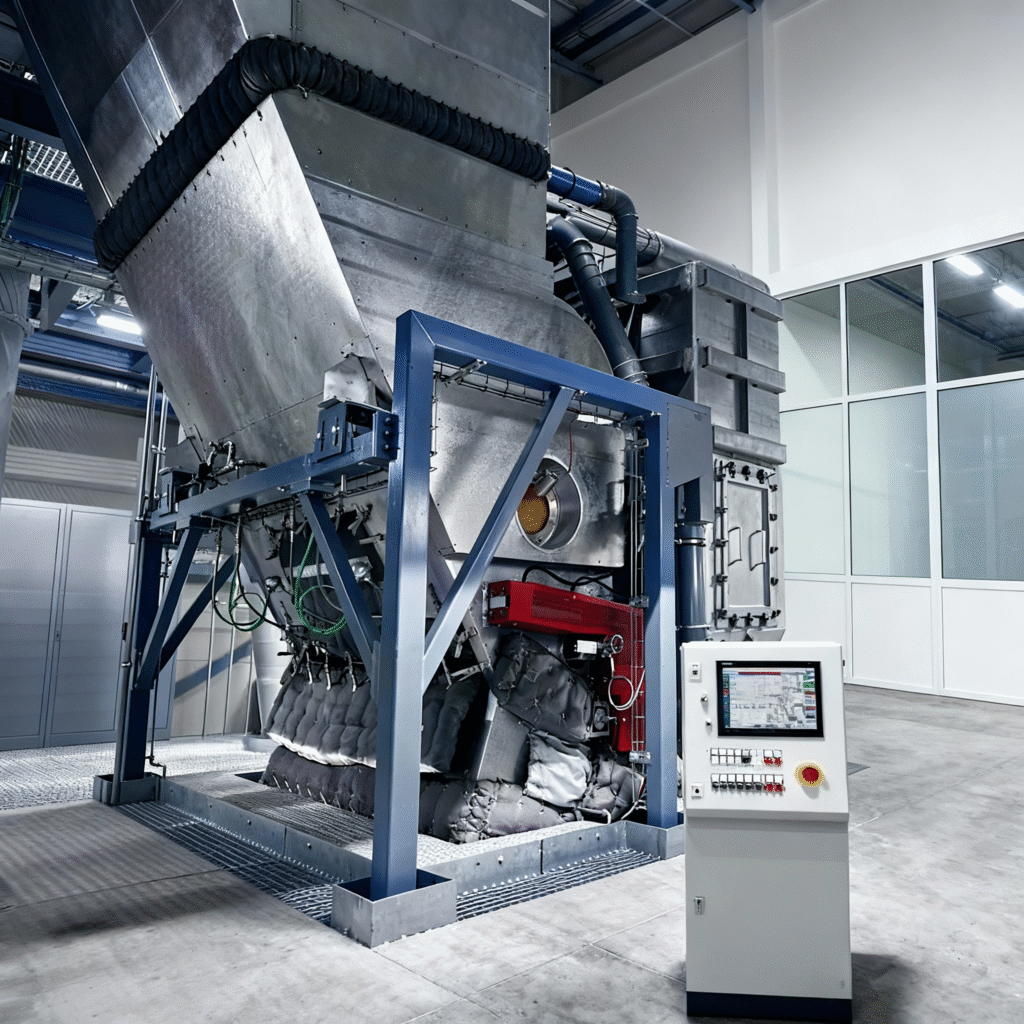

Neuhaus Neotec – Neoraost 30

Benefits-

- Mid-Scale. Flexible. Efficient.

- Roast 10–33 kg batches with precision

- Capacity flexibility: 30% to 110% of batch size

- Up to 240 kg/hour roasting throughput

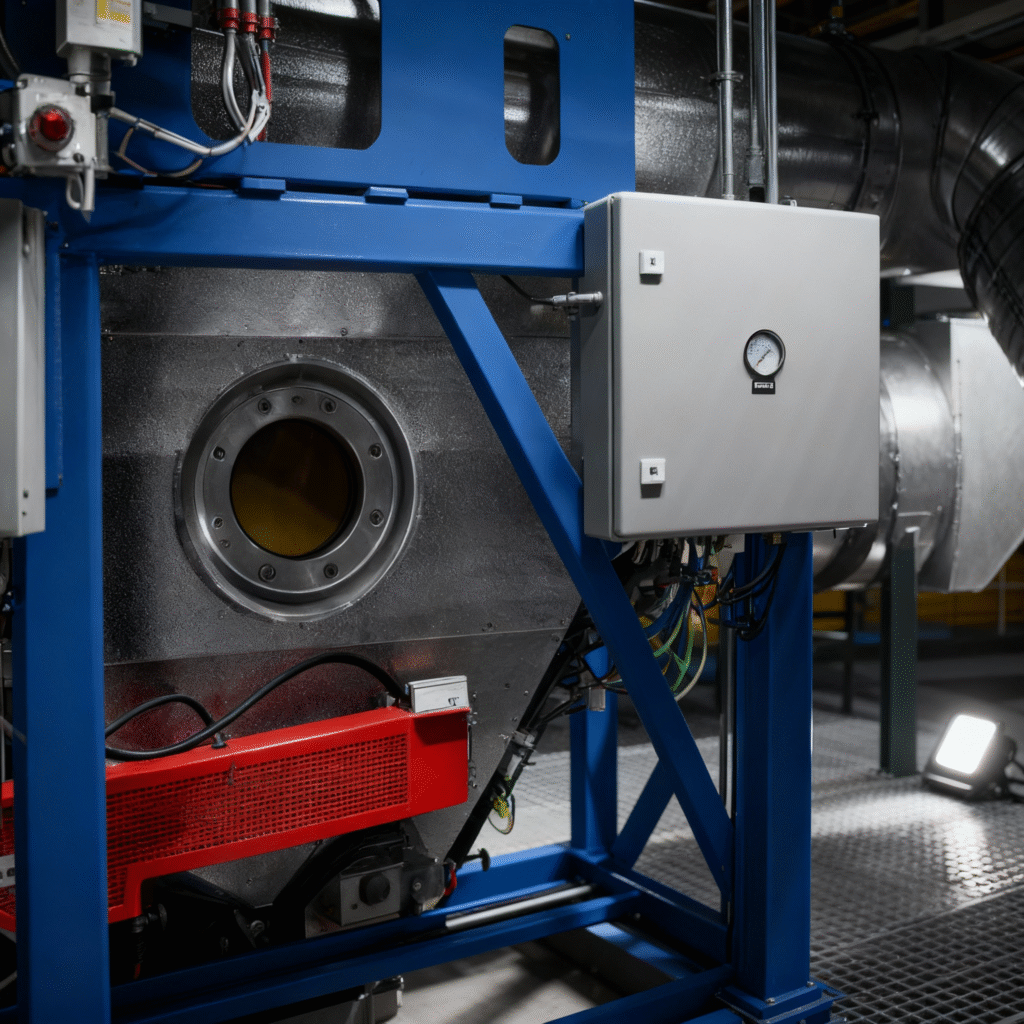

- Uniform hot-air (RFB) roasting technology

- Recirculated hot air reduces energy consumption

- Autonomous recipe management with NN-PROFILE integration

The Neoroast 30 is built for specialty coffee roasters expanding their capacity. Using Neuhaus Neotec’s RFB hot-air roasting system, it guarantees gentle, uniform roasting with precise control of profiles. The machine is exceptionally flexible, capable of running between 30% and 110% of batch capacity (10–33 kg). Thanks to recirculated hot air, it delivers energy savings while maintaining consistent roasting quality. Integration with NN-PROFILE, CROPSTER, and ARTISAN allows autonomous recipe management and detailed process monitoring. The roaster is also suitable for other foods such as nuts, adding versatility to production.

- Manufactured by Neuhaus Neotec

- Made in Germany.

- Batch Size: 10–33 kg per roast

- Capacity Range: 30%–110% of batch size

- Nominal Capacity: up to 240 kg/hour

- Control System: PLC/tablet with NN-PROFILE

- Integration: Data interface to CROPSTER and ARTISAN

- RFB hot-air chamber for uniform,

- efficient roasting,

- Flexible operation: 30%–110% of batch capacity,

- Hot air recirculation for energy efficiency,

- Autonomous recipe management with NN-PROFILE,

- Compatible with CROPSTER and ARTISAN analytics,

- Versatile—also suitable for roasting nuts

Product Statement

Flexible, efficient, and precise—the Neoroast 30 adapts from 30% to 110% of its batch size, delivering consistent quality and energy savings.