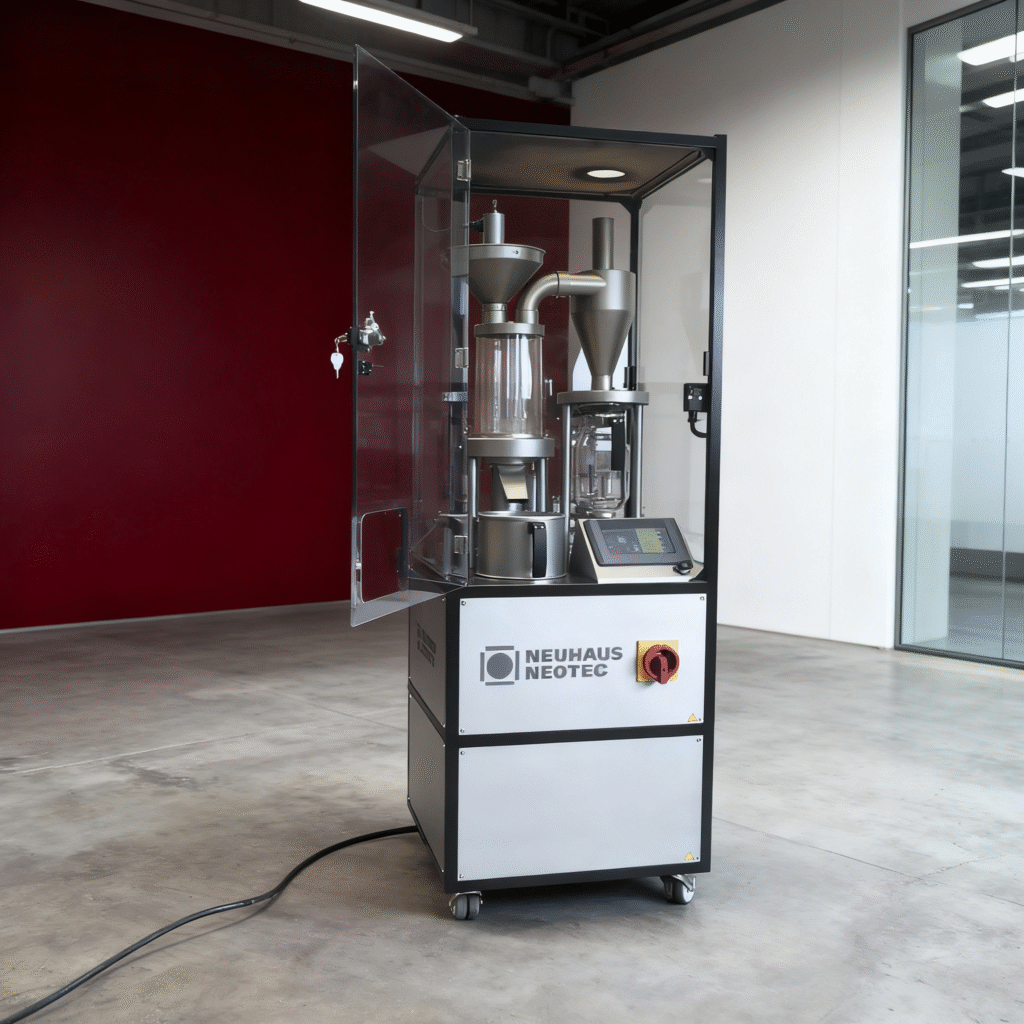

Neuhaus Neotec – RFB 250

Benefits-

- Roast 80–250 kg batches with flexibility

- Throughput up to 2,000+ kg/hour

- Hot-air recirculation saves significant energy

- Uniform results with RFB hot-air system

- Centralized control room for process monitoring

- Automated recipe storage & repeatability

- Fast heat-up times and changeovers

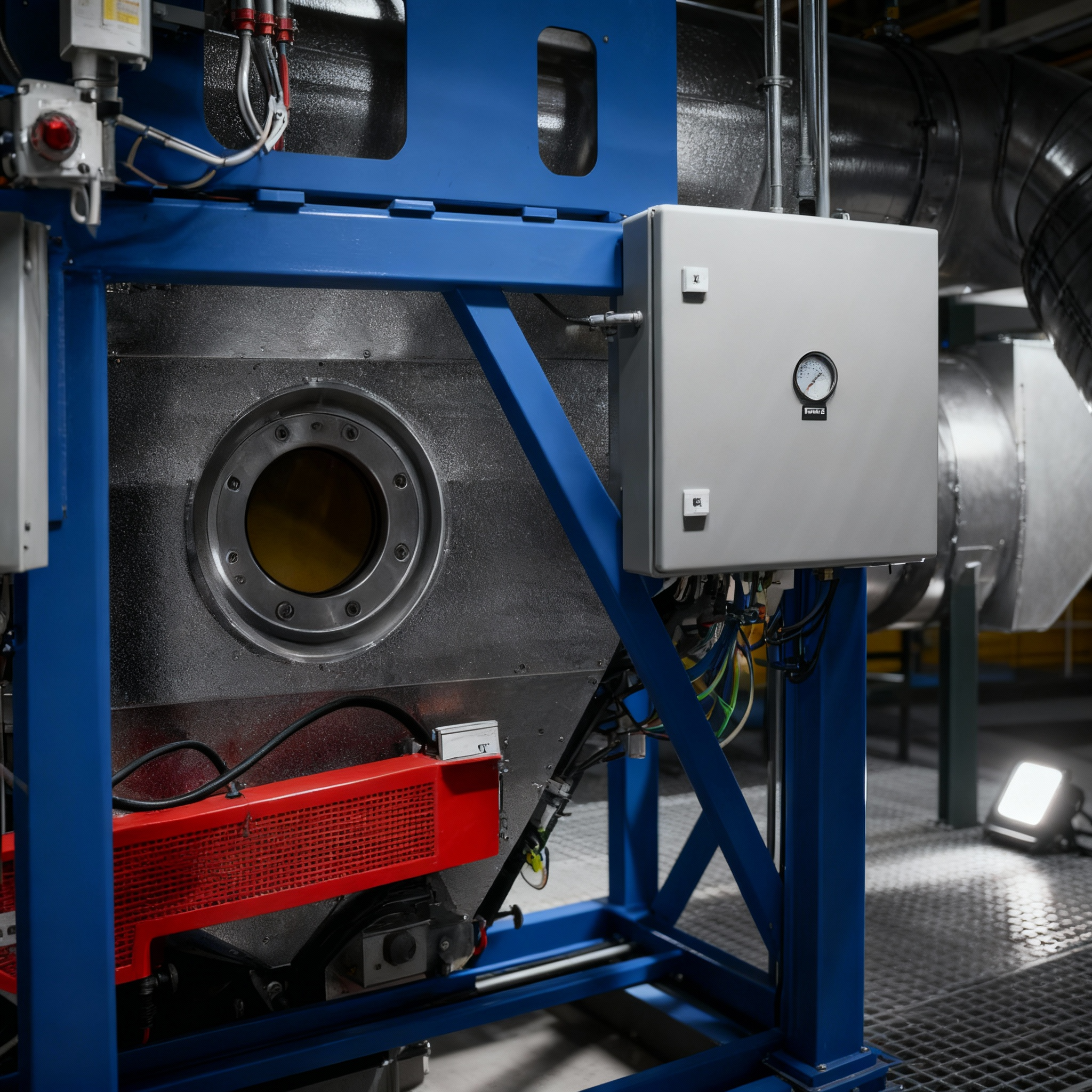

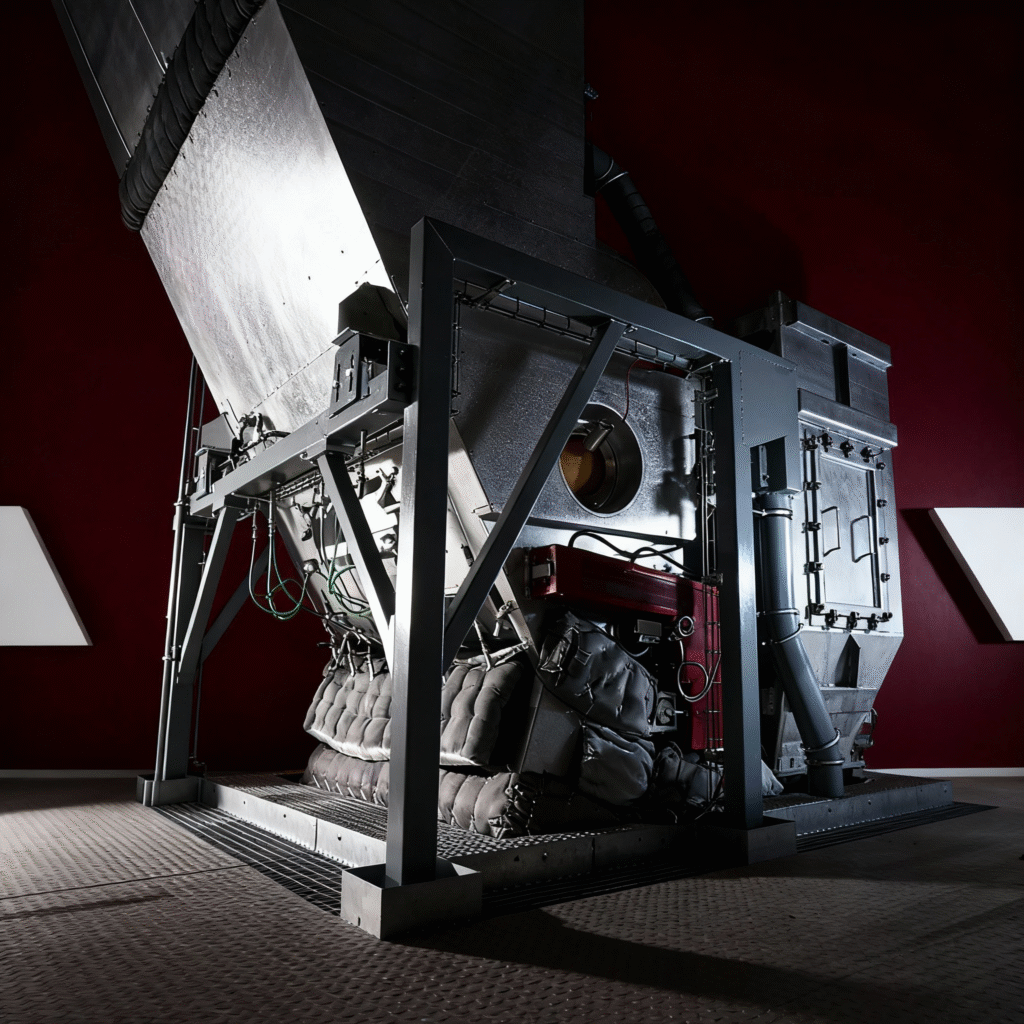

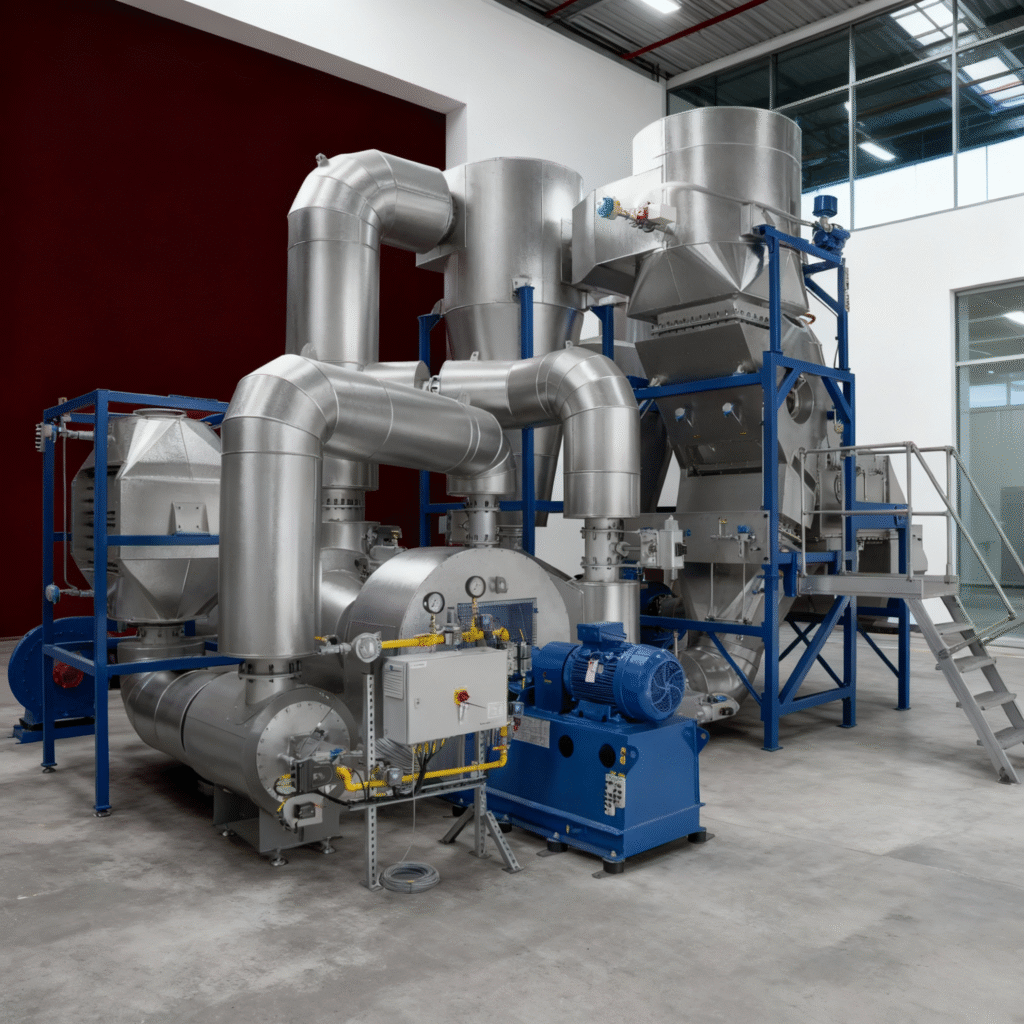

The RFB 250 is a mid-scale hot-air roaster designed for industrial roasteries demanding high throughput and flexibility. With batch sizes ranging from 80 to 250 kg and a nominal hourly output exceeding 2,000 kg, it provides consistent quality and energy efficiency. A dedicated control room simplifies recipe automation and process monitoring. Hot-air recirculation reduces energy demand, while optional green-coffee preheating increases output and efficiency even further.

- Manufactured by Neuhaus Neotec

- Made in Germany.

- Batch Size: 80–250 kg per roast

- Nominal Capacity: approx. 2,000 kg/hour

- Capacity Range: 30%–110% of batch size

- Control System: Centralized control room with recipe automation;

- Integration: Interfaces with CROPSTER and ARTISAN

- RFB hot-air chamber with recirculated air,

- Profile roasting with automated recipe management,

- Flexible operation (30%–110% of batch capacity),

- Short heat-up times and quick availability,

- Green-coffee preheating option: +15–20% output boost,

- double-digit energy savings,

- Exhaust cleaning solutions: catalytic, RTO, UV-C photo-oxidation

Product Statement

Flexible and powerful—the RFB 250 delivers consistent roasting with batch sizes up to 250 kg and industry-leading energy efficiency.