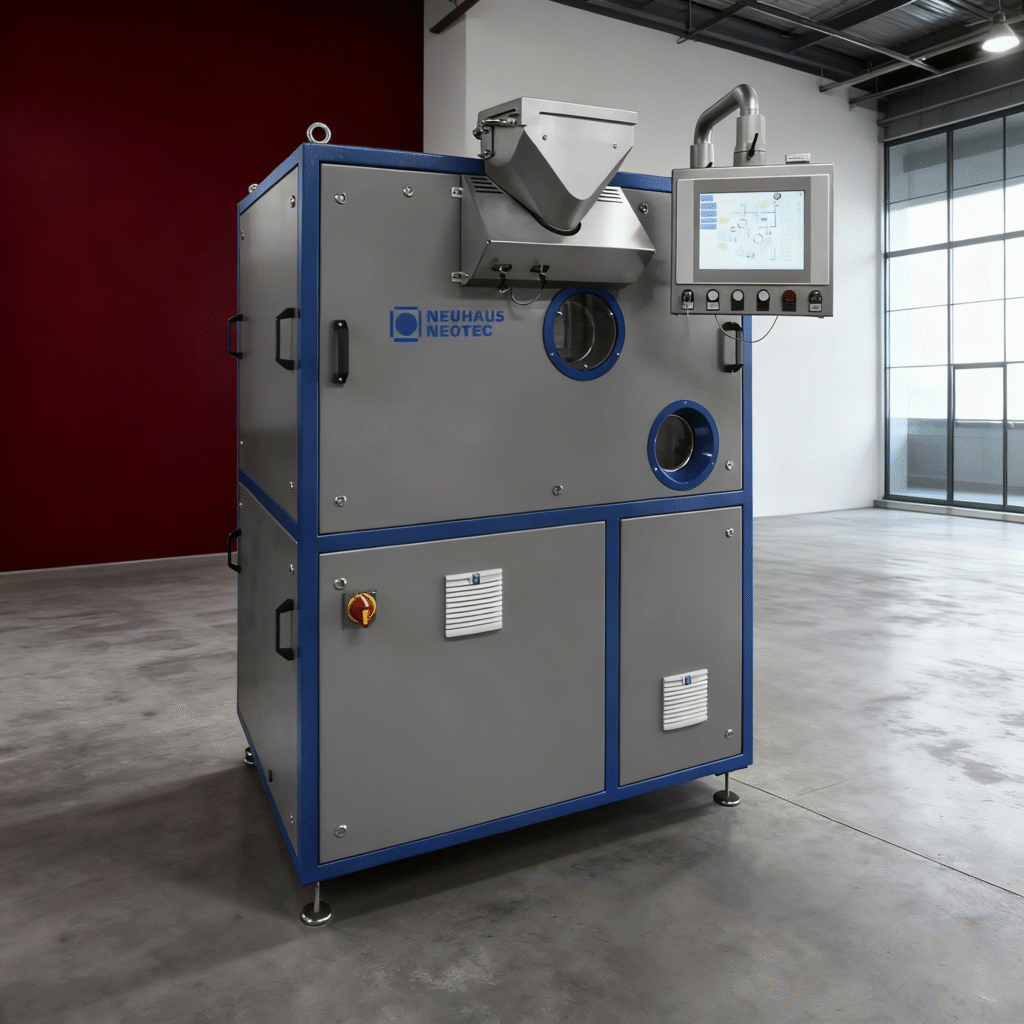

Neuhaus Neotec – RFB 300

Benefits-

- Large Batches. Reliable Control.

- Roast 100–300 kg per batch

- Throughput up to 3,000 kg/hour

- Uniform roasting via RFB hot-air system

- Hot air recirculation reduces energy costs

- Centralized control room with recipe automation

- Flexible operation: 30%–110% of batch size

- Quick heating and fast changeovers

- Built for industrial-scale, continuous production

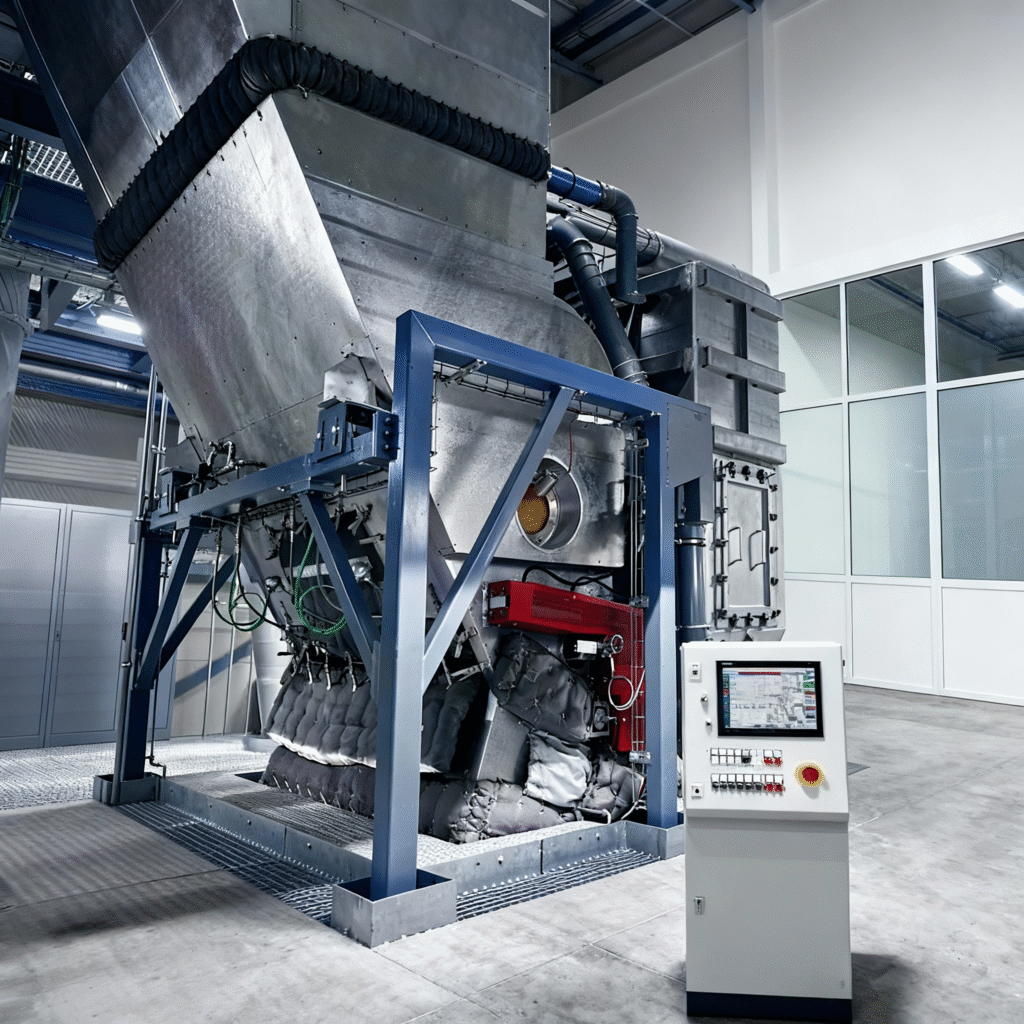

The RFB 300 is one of Neuhaus Neotec’s larger hot-air roasters, designed for large-scale industrial roasteries. With batch sizes up to 300 kg and throughput near 3,000 kg/hour, it ensures consistent results at scale. Its closed gas circuit with hot-air recirculation lowers energy consumption while delivering uniform roast quality. A dedicated control room provides centralized recipe automation, data logging, and process monitoring. Optional green-coffee preheating can further boost output and efficiency.

- Manufactured by Neuhaus Neotec

- Made in Germany.

- Batch Size: 100–300 kg per roast

- Nominal Capacity: approx. 3,000 kg/hour

- Capacity Range: 30%–110% of batch size

- Control System: Centralized control room with recipe automation

- Integration: Compatible with CROPSTER and ARTISAN

- RFB hot-air chamber with recirculated air,

- Automated profile roasting and recipe storage,

- Centralized control for monitoring & repeatability,

- Energy-efficient via closed gas circuit,

- Green-coffee preheating option improves output by 15–20%,

- Exhaust cleaning options: catalytic, RTO, UV-C systems

Product Statement

Engineered for scale—the RFB 300 delivers consistent roasting with large batch sizes, centralized control, and industry-leading efficiency.