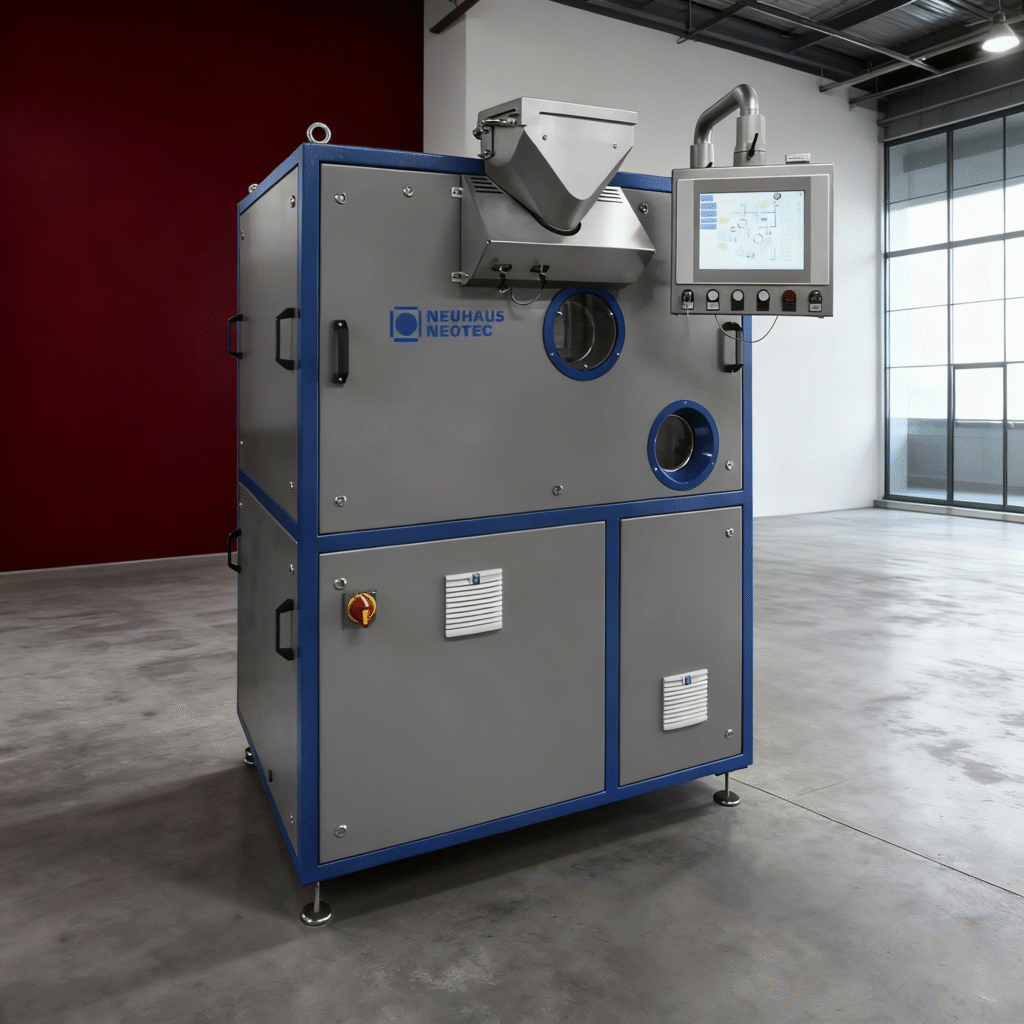

Neuhaus Neotec – Roller Grinder – LMW 100

Benefits-

- Lab Precision. Maximum Flexibility.

- Achieve reproducible grinding results

- Define precise particle size distribution

- Compact design for lab and QC use

- Two-stage grinder for maximum flexibility

- Quick and easy roll change system

- Water-cooled rolls for stable grinding

- Hygienic stainless steel contact parts

- Robust German build for long service

The LWM 100 is Neuhaus Neotec’s laboratory roller grinder, designed for quality control, recipe development, and small-scale production. Its compact design integrates all components into one housing with an isolated grinding chamber, ensuring contamination-free operation. With two-stage grinding, precise roll adjustments, and flexible control, it enables highly reproducible results. Electro-polished surfaces and stainless-steel contact parts ensure easy cleaning and compliance with the highest hygiene standards.

- Manufactured by Neuhaus Neotec

- Made in Germany.

- Roll Diameter: 250 mm

- Roll Length: 100 mm

- Circumferential Speed: up to 16 m/s (adjustable)

- Connected Load: 4 × 2.2 kW

- Collecting Bin: ~20 liters

- Special Features: Automatic roll disengagement if foreign particles enter

- Two-stage grinder for flexible lab applications,

- Quick clamping system for roll changes,

- Touch-screen PLC control with TIA portal

- Stainless steel product-contact parts,

- Optional bearing temperature measurement,

- Optional vibration cleaning system,

- Optional automatic vibration feeding unit

Product Statement

Compact but powerful—the LWM 100 ensures precise, reproducible grinding results for laboratory, QC, and small-batch applications.