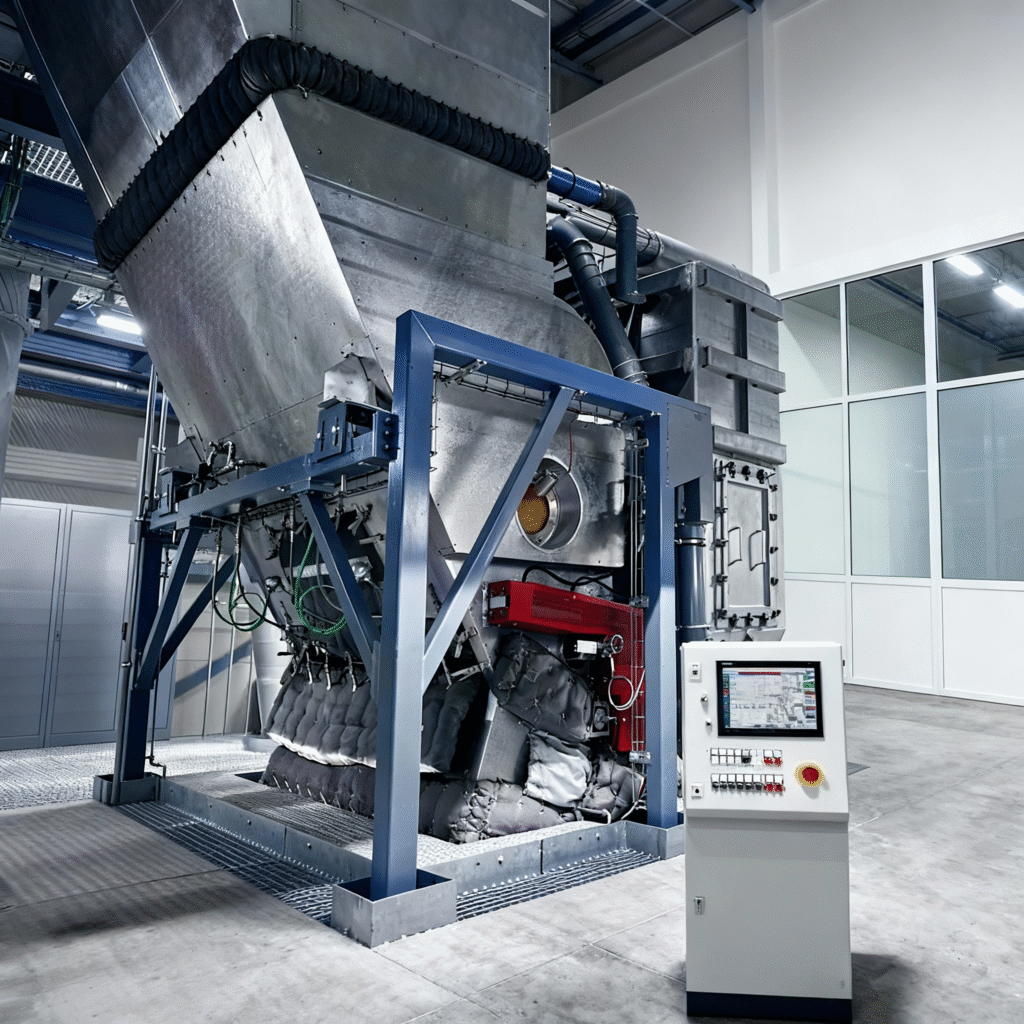

Neuhaus Neotec – Roller Grinder – WMS 100

Benefits-

- Versatile Grinding. Compact Power.

- Grind espresso, filter, instant coffee

- Multi-stage gradual grinding for uniform results

- Compact design for small to medium capacities

- PLC recipe control with motor-driven adjustments

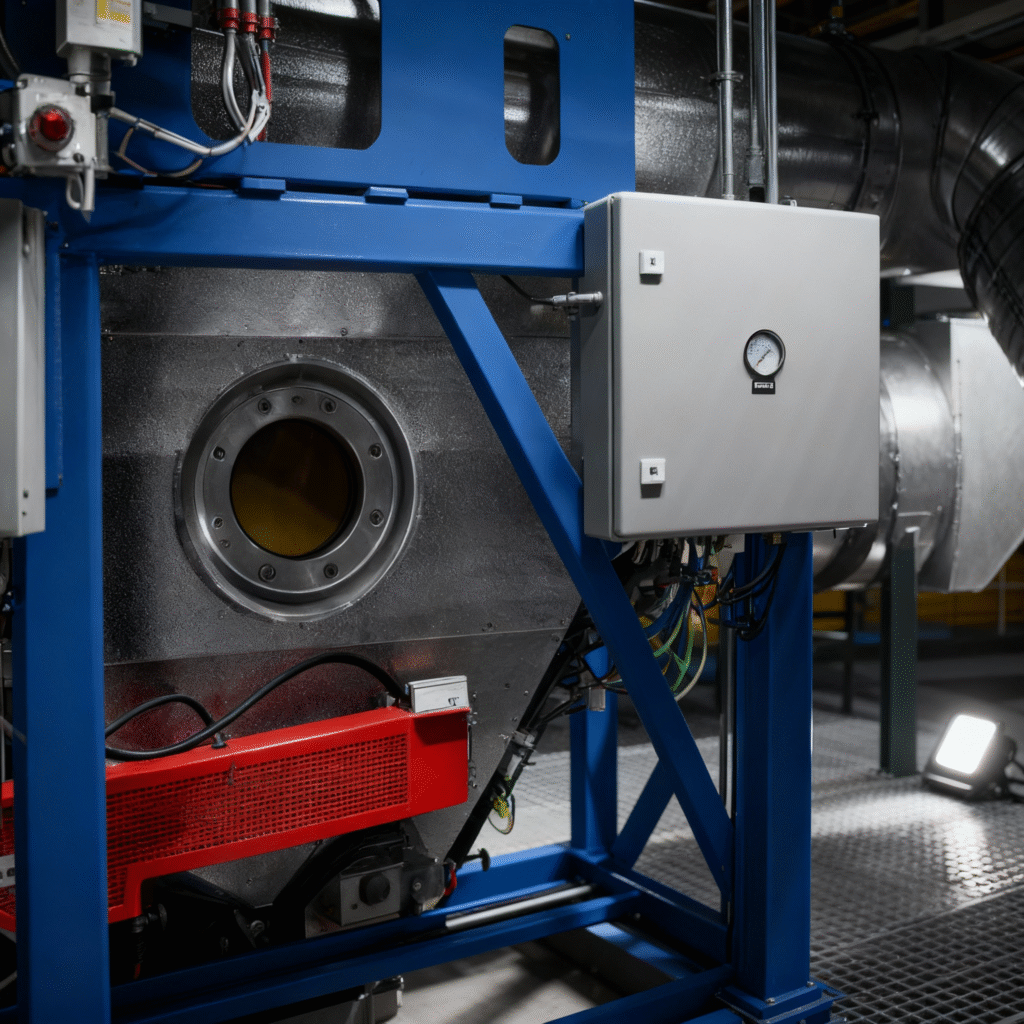

- Water-cooled rollers ensure stability

- Integrated compactor for density control

- Magnetic separator protects product quality

- Built for continuous industrial use

The WMS 100 is part of Neuhaus Neotec’s versatile WMS grinder series, designed for small to medium capacities. Available in single-, two-, or three-stage versions, it delivers precise and reproducible results across espresso, filter coffee, and instant applications. With options like PLC recipe control, motor-driven gap adjustment, water-cooled rollers, and integrated compaction, the WMS 100 ensures flexible operation and high efficiency. A compact footprint makes it ideal for both standalone use and integration into production lines.

- Manufactured by Neuhaus Neotec

- Made in Germany.

- WMS 22 (2-stage, 200 mm rolls): 300–500 kg/h, 1340 × 1260 × 1800 mm

- WMS 23 (3-stage, 200 mm rolls): 400–650 kg/h, 1340 × 1260 × 2440 mm

- WMS 42 (2-stage, 400 mm rolls): 600–1000 kg/h, 1540 × 1260 × 1800 mm; WMS 43 (3-stage, 400 mm rolls): 800–1300 kg/h, 1540 × 1260 × 2440 mm

- Instant models (e.g., WMS 42 I): up to 1400 kg/h

- Multi-stage,

- gradual grinding with high reproducibility

- Central drive or individual drives configurable,

- PLC with recipe management and motor-driven gap adjustment,

- Mixer with compaction for density control,

- Water cooling for stability and consistency,

- Magnetic separator in feeder for quality protection,

- Options: product temperature measurement,

- high-capacity compactor,

- sound insulation

Product Statement

From espresso to instant—the WMS 100 delivers versatile, compact, and precise grinding for small to medium capacities.